Whats the Sampke at the Start of Every Needledrop Review

Showtime Article Inspection Overview

Outset Article Inspection (FAI) consists of a detailed verification and comparison of a requirement (product design) versus results (production effect). A supplier needs to do a Get-go Article Inspection due to its industry requirements like AS9102 or client requirements earlier the manufacturing procedure begins.

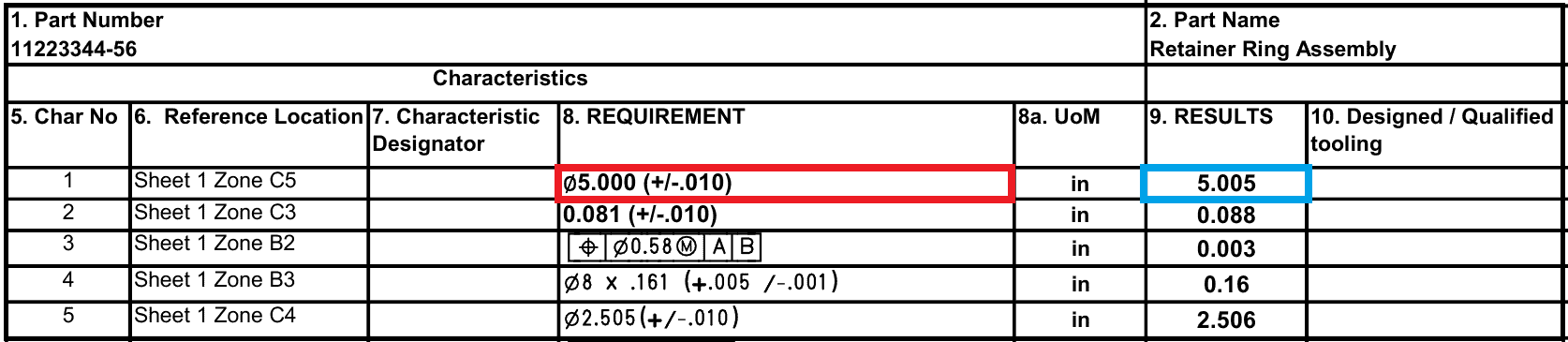

The part must conform to certain dimensional specifications. For example: Requirement #one is 5.000 inches in diameter with a plus or minus tolerance of 0.01. Upshot #1 is v.005. The result has conformed to the specification.

The part must conform to certain dimensional specifications. For example: Requirement #one is 5.000 inches in diameter with a plus or minus tolerance of 0.01. Upshot #1 is v.005. The result has conformed to the specification.

• What is a First Article?

• What is a First Commodity Inspection?

• Offset Article Inspection Process Flow

• What is a First Commodity Inspection Report?

• How to create a First Article Inspection Report step-by-step

• What is a ballooned drawing?

• When should First Article Inspection exist performed?

What is a Outset Article?

A start article is the first detail that is manufactured using the aforementioned product processes as mass production by whatever subcontracted factory or supplier.

Then that the customer can validate how the supplier is capable of producing parts, and assemblies that come across all engineering and blueprint requirements on a mass scale.

What is a First Article Inspection?

One time a new or revised part is manufactured on the first product run, it is necessary to ensure that all requirements (such equally the specific drawings and specifications) have been met by inspecting a random sample of the starting time product run. This is called "First Article Inspection (FAI)".

In First Commodity Inspection, many organizations inspect every single dimension and specification of this sample against the drawing, as part of the detailed verification of product results versus product pattern, before the manufacturing process begins.

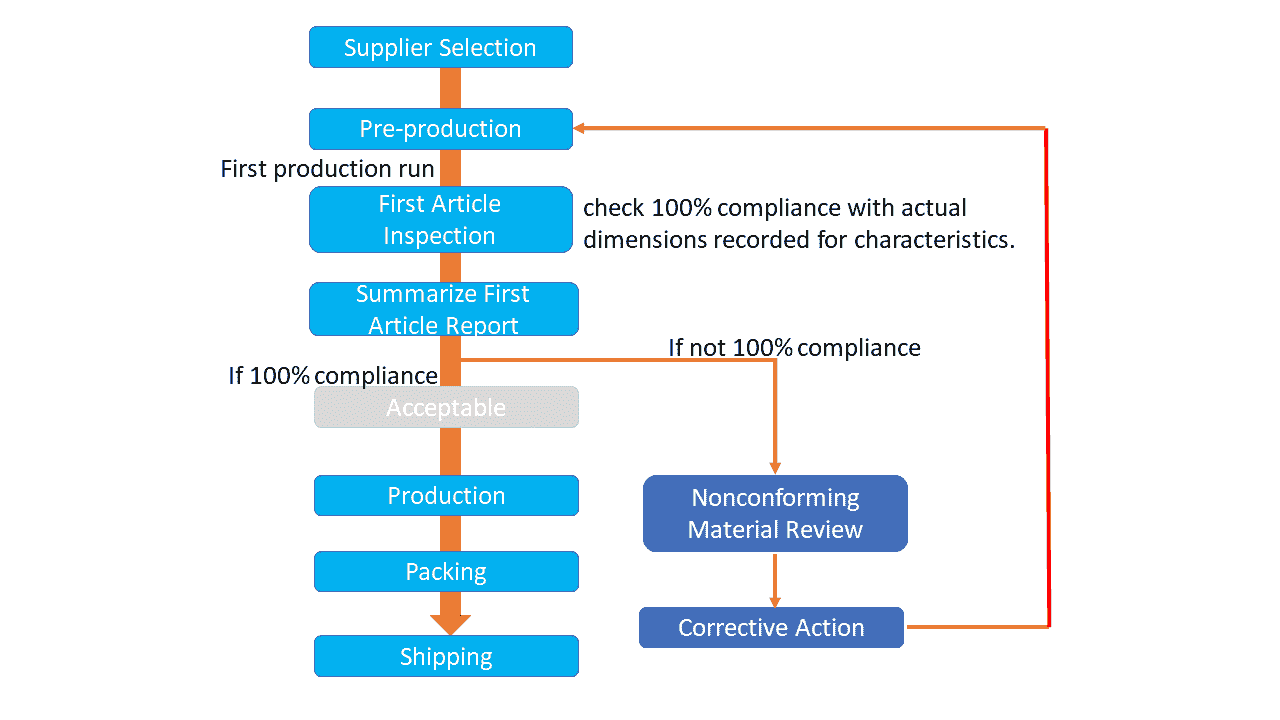

First Article Inspection Process Flow

Beneath is an example of the Offset Article Inspection Process Flow. First Article Inspection is conducted during the offset production run. If you lot observe something, non 100% compliant to requirement, you lot need to take the corrective action.

Download Free First Article Inspection AS9102B Template & Input Guide

What is a First Article Inspection Written report?

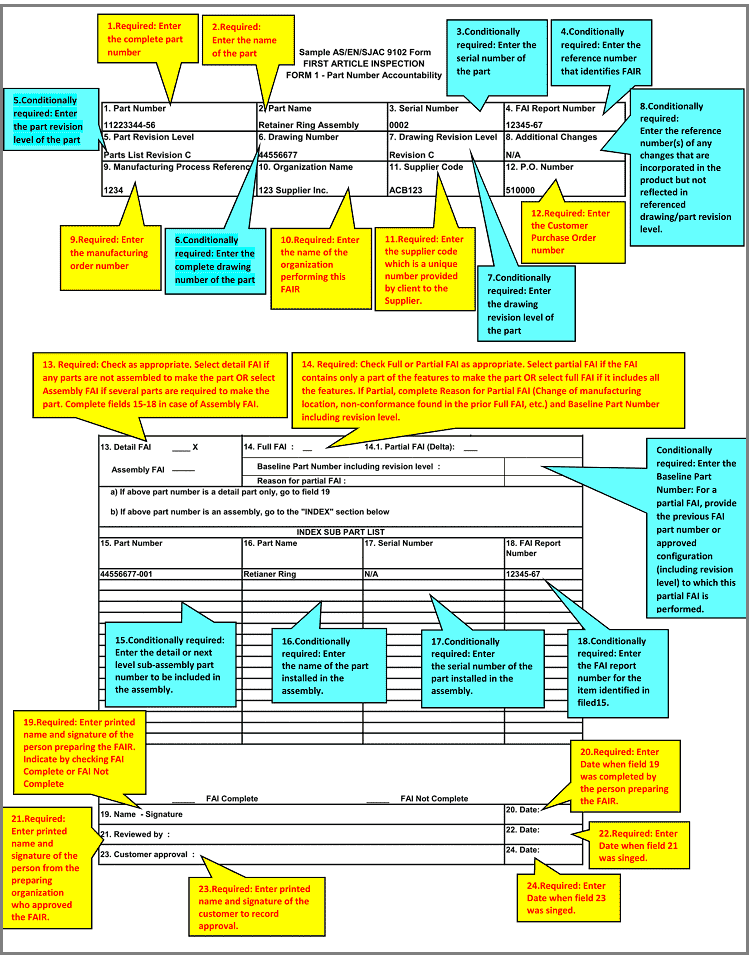

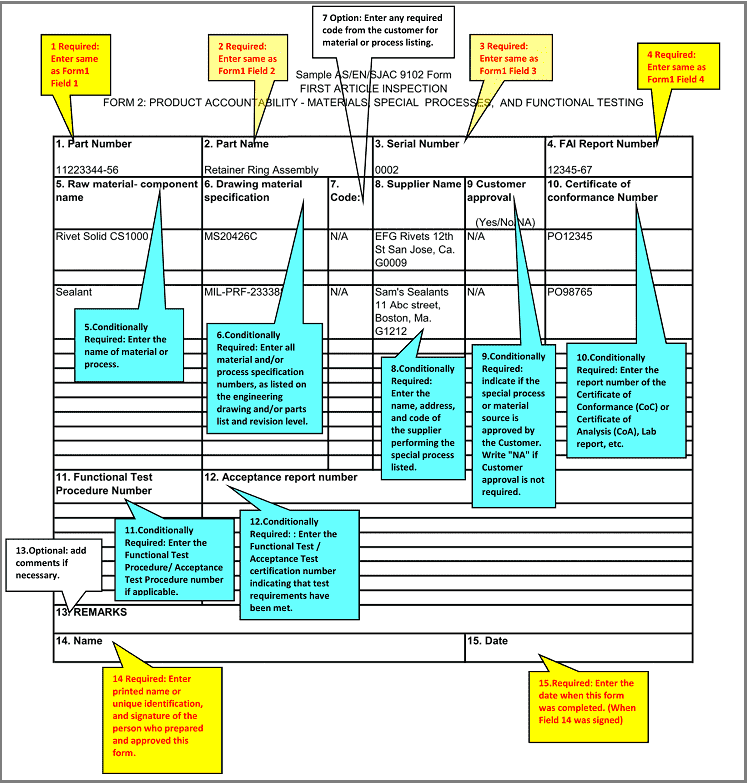

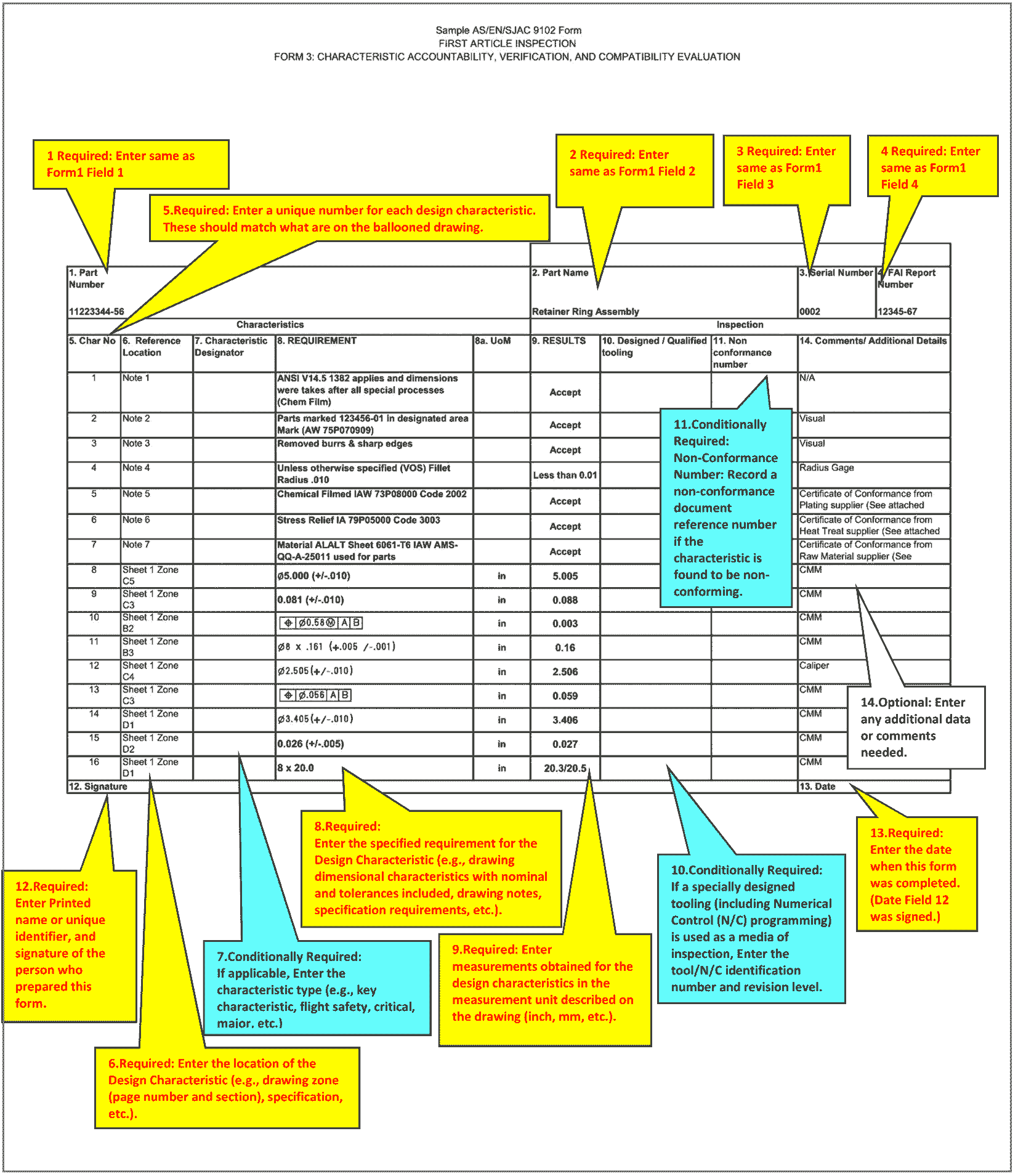

To validate that a product has been manufactured to the correct specification, First Article Inspection Report (FAIR) consists of three forms (form 1 Part number accountability, course 2 Production accountability and form 3 Feature accountability) plus 1 ballooned cartoon.

The necessity of fields to be filled out depends on filed color:

• Yellow - Required fields

• Blue - Conditionally required fields

• No colour (white) - Optional fields

How to create a Beginning Commodity Inspection Report step-by-step

Form 1: Part number accountability – this form is used to summarise the part of the article that is being first inspected (FAI part) and associated sub-assemblies or detail parts.

Download Free Starting time Article Inspection AS9102B Template & Input Guide

Form ii: Production accountability – is used for all raw materials, specifications, processes and functional tests defined equally a design requirement.

Form 3: Characteristic accountability – is used to summarise actual specific pattern characteristics such as dimensions, tolerances, drawing notes, etc. likewise as bodily measurement results of the first commodity inspection parts for every design feature on the cartoon.

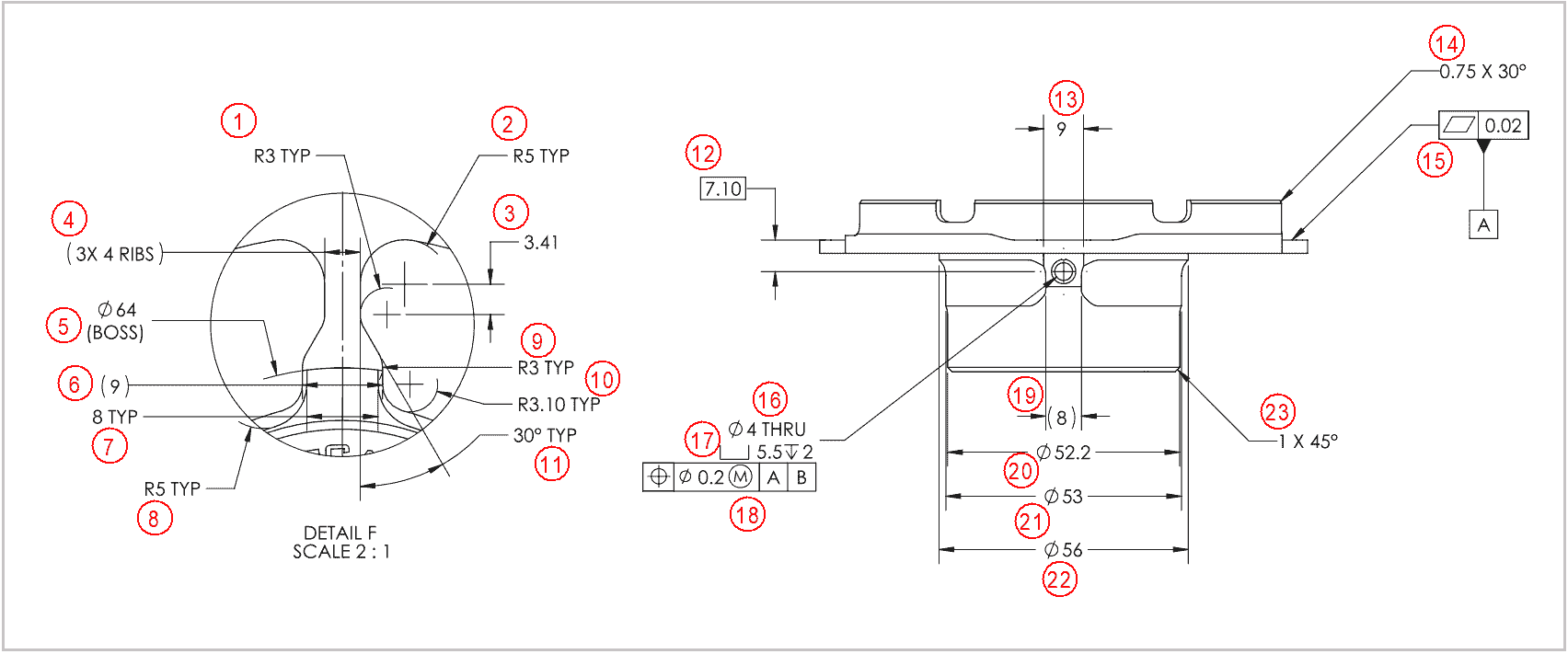

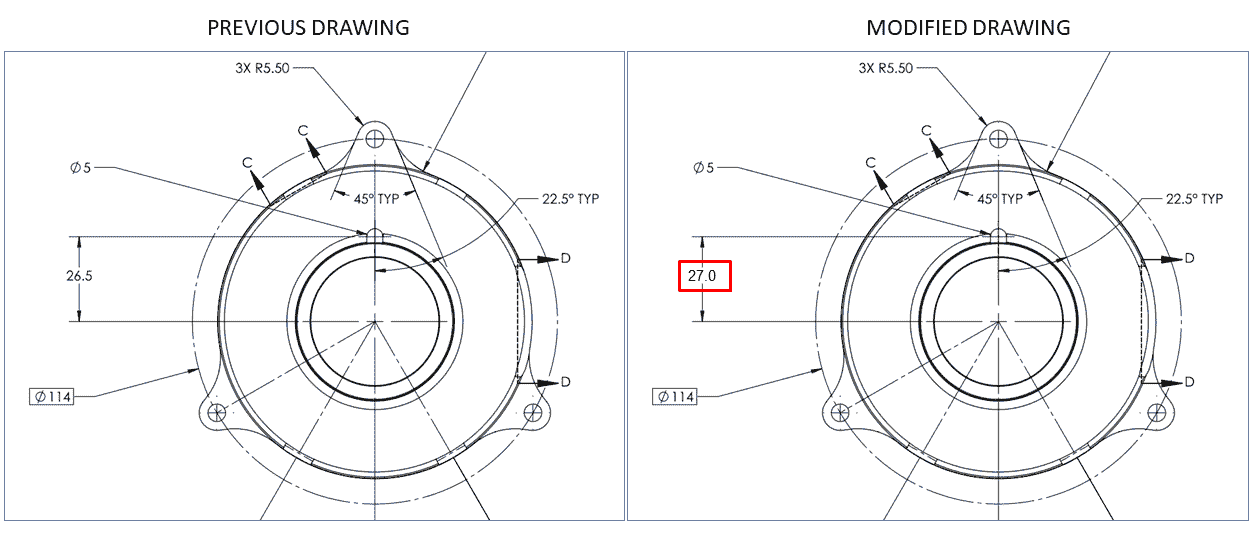

What is a ballooned drawing?

Airship Cartoon (besides called Bubble Drawing) – is an essential part of a First Commodity Inspection Report package to support Grade 3 and to verify every blueprint feature requirement. In this drawing, each blueprint characteristic has its ain uniquely numbered balloon. For traceability purposes, this number needs to match with the characteristics numbers on Course 3. Even so, creating ballooned drawings and first article inspection reports by hand is time-consuming and labor-intensive.

Ballooned Drawing Example (To solve this problem, nosotros offer our Auto Ballooning Software, QA-CAD which helps you lot to create a First Article Inspection Report EXCEL file and a ballooned cartoon file instantly.

Ballooned Drawing Example (To solve this problem, nosotros offer our Auto Ballooning Software, QA-CAD which helps you lot to create a First Article Inspection Report EXCEL file and a ballooned cartoon file instantly.

To speed upward your beginning article inspection report paperwork drastically, this machine ballooning characteristic is essential.

This auto ballooning feature can not only add balloons next to all dimensions but likewise extract all selected dimensions and GD&T feature control frames at one time and export captured information to a outset article inspection study EXCEL file. Our QA-CAD software has a more accurate and faster car ballooning characteristic for PDF files.)

Example: Car Ballooning Feature for PDF files

Example: Car Ballooning Feature for PDF files

When should Beginning Article Inspection be performed?

Once all designs and production processes take been finalized, a full FAI must be performed on the outset production run. On the other manus, partial FAI should be executed when at that place is any alter in the design or manufacturing process that affects the fit, course or function of the production.

Total FAI is necessary when i of the post-obit occur:

• New part introduction

• New supplier or new location of manufacture

• When this role has not been manufactured for more than two years

• When the customer requested

Full FAI is required past a new supplier, a new factory and new part introduction

Full FAI is required past a new supplier, a new factory and new part introduction

Delta FAI (Partial FAI) is necessary when one of the following occur:

• Design change which tin can potentially affect fit, form or role

• Production procedure change (eastward.g. tooling, materials, processes, inspection method, automobile, NC programme, product manufacturing process, etc.).

• Change to a different media programme that can potentially affect fit, course or part

Design change

Design change

brooksbeggersewen.blogspot.com

Source: https://www.guthcad.com/blog/first-article-inspection.html

0 Response to "Whats the Sampke at the Start of Every Needledrop Review"

Post a Comment